Industry-leading metrology software with powerful tools for quick and easy 3D scan data capture and interpretation.

Streamline 3D scan data capture and processing with the industrial Control X quality control and dimensional inspection software. Measure with Artec 3D scanning before analyzing and sharing results with greater automation, assurance, and freedom to ensure quality anywhere – whether it be avoiding design flaws or improving factory efficiency.

Use Control X to assess prototypes and address the issues that make parts difficult to manufacture such as deformation after molding or casting.

Reduce costly scrap waste caused by constantly having to rework parts, and reach your final design more quickly, with Control X deviation analysis and dimensioning tools.

Scanning can reveal wear or deformation in unexpected places. Locate and scrutinize part damage with ease using an advanced, automated alignment and deviation analysis toolset.

Go beyond simple alignment and color mapping – Control X has all the tools needed to meet demanding quality control applications and solve the most complex metrology challenges.

Many inspection programs can identify deviations. But Control X’s unique Design X and CAD integration allows users to directly update models to compensate for problems.

Monitor geometry changes over time to take corrective action as issues arise. With Control X trend analysis and reporting, you can even predict when a part or tool is likely to fail.

Control X is so intuitive, you don’t have to be a highly trained or experienced metrologist to use it. Along with the accessibility and portability of Artec 3D scanning, this allows more people in your organization to start accelerating part inspection.

Struggling to manufacture certain parts? Use Artec 3D scanning to take a closer look, then carry out Control X analyses to understand how to get production back on track.

Create a complete digital record of a part’s geometry so you can perform further analysis when it’s no longer present. Discover an issue six months from now? Just pull up the scan and check any dimension – no need for remeasuring.

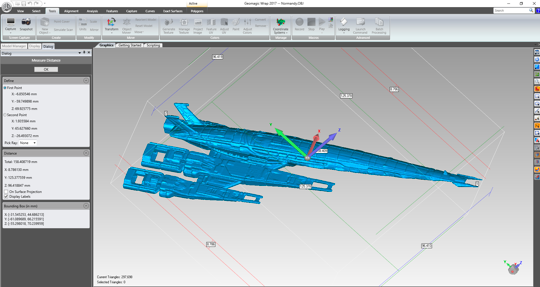

With the great combination of 3D scanning and Geomagic Wrap, you can effortlessly create elaborate works of art and scale sculptures, as well as archive and fully restore fragile or eroded artefacts. Artists and sculptors across the globe use Geomagic Wrap to represent physical objects in 3D design environments, delivering precise 3D data in a wide range of industry-standard formats.

As a powerful 3D design software, it is purpose-built to seamlessly get your creation straight into production. It includes robust interoperability tools to handle the import and export of 3D file formats like STL, OBJ, PLY, IGES, STEP and other neutral formats. Freeform Plus supports additional CAD formats. Combine CAD files with sculpted features to create accurate organic solids that are defined by explicit dimensions.

Go further than traditional CAD software ever would. Experience the flexibility and advantages of this hybrid modeling system, which includes Surfaces, Solids, Mesh, SubD, and Clay.

The software also gives its users an opportunity to create both smooth surfaces and razor sharp edges with SubD, model precisely defined CAD shapes with NURBS and Solids or deform and emboss shapes with Clay.

This professional software includes a Geomagic® Touch® device, a true 3D interface which provides force feedback. Users are offered to choose between Geomagic® Touch X™ and Geomagic® Touch™ haptic devices.

Paired with a powerful and highly precise 3D scanner, Geomagic Wrap has multiple applications in archaeology. It is usually used to capture intricate petroglyphs and ancient markings, often undetected by the naked eye, for consecutive analysis and archiving. Also, the software’s direct 3D print capabilities give students and museum visitors the freedom to experience ancient artefacts no matter where they are.

Geomagic Wrap is the industry's fastest and most easy-to-use 3D reverse engineering software with automated, smart tools for visualizing and transforming point cloud and model data into usable 3D models.

Contact

info@voxel3dtech.com

+91 8750901174

Noida office:

B-52, B Block, Sector 64, Noida, Uttar Pradesh 201307

Mumbai Office :

Santacruz east, vakola 400055, Mumbai

Copyright 2025 © All rights Reserved